Full size / Grand Opening: Canada’s first proprietary solvent extraction cell technology for REE processing was presented by the Saskatchewan Research Council (SRC) in May 2023. (Source)

Disseminated on behalf of Commerce Resources Corp. and Zimtu Capital Corp.

Which will come first in Canada, the mine or the facility to process rare earths? Although there‘s no active rare earths mine in Canada at the moment, a commercial minerals-to-metals processing plant for demonstration purposes is being built by the Saskatchewan Research Council (SRC), an agency of the provincial government. SRC‘s President and CEO, Mike Crabtree, sees this “chicken-and-egg situation“ clearly in favor of building first the front-end to then give “nascent mine operations off-take agreements“ and “a route to market rather than having to sell that product to China“. MP Materials Corp. is producing such a product, a mineral concentrate, from its Mountain Pass Mine in California, but has to ship it to processors in China as there is no adequate facility in North America yet to produce the higher value rare earth metals. MP Materials is currently building its own processing plant in the United States, but SRC‘s facility will likely be first to come online, slated to be operational in late 2024. As SRC is not a mining company, it is already looking for adequate sources to feed its Rare Earth Processing Facility.

Today, Commerce Resources Corp. announced the signing of a Letter of Intent with the Saskatchewan Research Council (SRC) to deliver amounts of the Mixed Rare Earth Carbonate (MREC) produced from the Ashram Rare Earth and Fluorspar Deposit to SRC‘s Rare Earth Processing Facility in Saskatoon.

According to today‘s news-release: “The intention of this collaboration is to complete the first full rare earth element supply chain in Canada from mine to metal. SRC is constructing North America’s first fully integrated Rare Earth Processing Facility, spanning the stages from minerals to metals. The Facility is expected to be fully operational in late 2024 and has already demonstrated each individual stage including NdPr metal ingots.“

Commerce Resources‘ President and CEO, Chris Grove, commented: “We are pleased to sign this letter of intent with SRC, who is positioned to become the first commercial REE processor in Canada. We are happy to provide, once in production, amounts of our Mixed Rare Earth Carbonate concentrate from our Ashram Deposit to SRC in Saskatchewan.”

About the Saskatchewan Research Council: SRC is Canada’s second largest research and technology organization. With nearly 350 employees, $232 million in annual revenue and more than 75 years of experience, SRC provides services and products to its 1,600 clients in 22 countries around the world. For more information, go to www.src.sk.ca.

About the Ashram Deposit: The Ashram Deposit ranks as one of the largest REE (and fluorspar) deposits globally, consisting of a monazite dominated (i.e., strong NdPr), single mineralized body outcropping at surface, and has a drill delineated footprint of over 700 m along strike, 300 m across, and 600 m deep, and remains open at depth. The deposit hosts a measured resource of 1.6 million tonnes (Mt) at 1.77% rare earth oxide (REO) and 3.8% F, an indicated resource of 27.7 Mt at 1.90% REO and 2.9% F, and an inferred resource of 219.8 Mt at 1.88% REO and 2.2% F, at a cut-off grade of 1.25% REO (Effective Date July 5th, 2012). Note, mineral resources are not mineral reserves as they do not have demonstrated economic viability. There is no certainty that all or any part of the Mineral Resources will be converted into Mineral Reserves.

NI 43-101 Disclosure: Darren L. Smith, M.Sc., P.Geo., Dahrouge Geological Consulting Ltd., a Permit holder with the Ordre des Géologues du Québec and ‘Qualified Person’ as defined in National Instrument 43-101 – Standards of Disclosure for Mineral Projects, supervised the preparation of the technical information in this news release.

“SRC, an agency of the Saskatchewan Government, has been working on rare earth elements for over 15 years, establishing them as pioneers in the field. Crabtree praised SRC‘s efficiency in developing and commissioning solvent extraction cells within five years. This accomplishment, made possible by the dedicated efforts of their staff, positions SRC as one of the leading authorities in Canada and North America. With the fifth-largest reserves in the world, Canada is poised to play a vital role in the global rare earth elements industry, making it a significant player in the 21st-century global economy, according to Crabtree. He compared the importance of rare earth elements to that of oil and gas in previous years, highlighting the opportunity for Canada to supply value-added products... Currently, under construction SRC‘s fully integrated, commercial demonstration Rare Earth Processing Facility in North America is expected to be fully operational by late 2024. The facility will incorporate hydrometallurgy, separation, and metal smelting stages, solidifying Saskatchewan‘s status as a cutting-edge rare earth element hub.“ (Source)

Excerpts from “Building the Rare Earth Element Supply Chain: Challenges and Opportunities“ (SRC in August 2022):

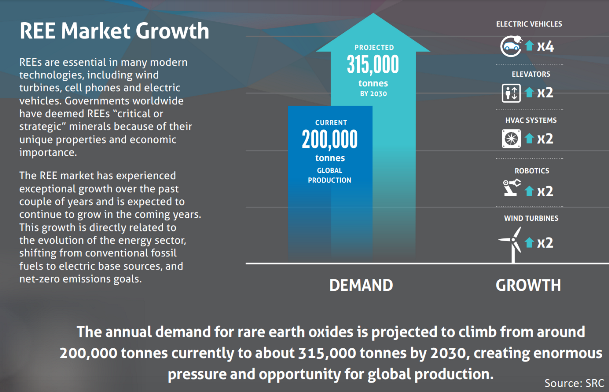

“The rare earth element (REE) market has experienced impressive and unprecedented growth over the past couple years, and it is expected to continue that growth in the coming few years. There are many reasons for this growth including a move toward electric vehicle adoption, net zero goals at both domestic and international levels and a secured supply of REEs that is no longer dependent on foreign sources. SRC hopes to be a contributing factor in this continued industry growth as it builds its Rare Earth Processing Facility and REE hub... For the REE industry, the key to success will come from the development and security of its own independent supply chains...[With] the massive demand required in the coming years, many [...] REE mines will need to begin production in order to meet the need and create a secure supply beginning from the upstream portion of the supply chain... The annual demand for rare-earth metals is projected to at least double by 2030, creating both enormous pressure and opportunity for global production...In Canada, SRC’s Facility is playing a leading role in addressing some of the issues in the supply chain, providing rare earth producers with a potential route to market and completing the important mid-stream piece of the supply chain by completing concentration and separation at the early stage of project development – a previous place of bottleneck for industry within the supply chain... SRC’s Facility is currently being completed in two phases. The first, which includes a Monazite Processing Unit, will process the ore and produce mixed rare earth, and be operational in early 2023. The second phase, which includes a Separation Unit and a Metals Unit that will produce rare earth metals, a key ingredient used to manufacture permanent magnets. These will be operational in early 2024.“

“The processing facility, once up and running, will process minerals mined in Saskatchewan, other places in Canada and across North America.“ (Mike Crabtree, SRC‘s President and CEO, in May 2023)

“Monazite is a source of mainly so called “light” REEs (especially cerium, lanthanum, praseodymium, neodymium) which are some of the critical elements for the permanent magnets used in clean technologies. SRC will work with the mining industry to secure this feed stock from across Saskatchewan, Canada and internationally.“ (Source: SRC)

“The Saskatchewan Research Council Rare Earth Processing Facility is going to be a catalystfor the growth of this industry sector. There are a lot of opportunities for collaborations in terms of the expansion of the existing facility...“ (Dr. Muhammad Imran, Vice-President of SRC’s Rare Earth Element Division, in October 2022)

“With its world-leading REE expertise, SRC is already working with industrial partners to develop company-specific REE concentration facilities in Saskatchewan, which is the precursor process to full REE processing. This Facility will allow for an environmentally sustainable, reliable, and strategic supply of REEs to be produced outside of China.” (Mike Crabtree, SRC‘s President and CEO)

Full size / Source / “On May 25, SRC celebrated the grand opening of its solvent extraction fabrication facility. This facility is a milestone in the construction of SRC’s Rare Earth Processing Facility, which requires 140 cells to separate rare earths into valuable individual rare earth oxides. These proprietary cells are being designed with artificial intelligence automation, which will increase productivity and help to kick start Canada’s rare earth supply chain. With this, SRC is now one of only a handful of jurisdictions worldwide with the capability to design and manufacture solvent extraction cells for REE processing.“ (Source: SRC)

”The Saskatchewan Research Council (SRC) is taking rare earth mineral processing to the next level. The organization is manufacturing 140 commercial-scale solvent extraction cells at it’s Saskatoon fabrication facility, which should be done by this fall. The cells separate the ores by taking a liquid called rare earth chloride through a process that then separates them into individual or grouped rare earth oxides.President and CEO of the Research Council Mike Crabtree says these extraction cells will be used at SRC’s Rare Earth Processing Facility, which is under construction and is expected to be complete by late next year. “The cells are about the size of an SUV... they look like water tanks, but they have complex internals that are designed to progressively separate these rare earths,” Crabtree said. “They will be located at our 51st Street facility as part of the wider and larger rare earth facility that we’re building. They will have their own 40-thousand square foot building... and if you want put this as an analogy in terms of an oil and gas refinery, they are the central part of the Rare Earth Refinery.” [...] Once everything is completed, Crabtree says it will be the first facility of its kind in Canada “and likely to be the first facility of its kind operational in North America as a fully integrated rare earth facility.” He noted “two or three” similar facilities are being built in the U.S., but believes theirs will be the first to be operational. Crabtree adds the potential economic benefit is there, as the value of processed rare earths can go up to $200-thousand per ton, compared to $10-thousand per ton if it was mined and exported. “There is 10 to 20 times uplift in value if we as Canadians not only mine these rare earths but process them and refine them for domestic and export sale.” (620 CKRM on May 26, 2023)

Full size / Source / “SRC has opened a fabrication facility in Saskatoon to manufacture the cells for the under construction rare earth processing facility.“ (Source)

“SRC is manufacturing 140 of these cells at the fabrication facility by fall 2023. The cells will be the main component in the rare earth processing facility’s separation unit. The cells take mixed rare earth chloride, a liquid mixture which includes all 17 rare earth elements, through a process that separates them into individual or grouped rare earth oxides. When separated, rare earth elements are highly valuable and are usedin a variety of modern technological end-uses including cell phones, electric vehicles and wind turbines, along with more strategic uses including for the defense industry... SRC is constructing North America’s first fully integrated, commercial, demonstration rare earth processing facility with hydrometallurgy, separation and metal smelting stages, which is expected to be fully operational in late 2024.“ (Source: Mining.com on May 25, 2023)

”The facility has been designed to process about 3,000 tonnes of monazite concentrate into 1,600 tonnes of REEs annually, of which 400 tonnes will be a neodymium praseodymium (NdPr) alloy. The facility will also produce REEs that can be used in the defence industry. “We’re calling this a research demonstration and commercialization plant,” Crabtree said. “A full-scale plant might be 10,000 tonnes.” Even at a third of the scale of a full-size plant, Crabtree said 400 tonnes of NdPr alloy is enough to provide material for half a million electric vehicles. The midstream facility will be sourcing monazite mainly from Brazil, but SRC is looking at Europe, Africa and Southeast Asia as other sources of monazite. Currently, there are no commercially operating rare earths mining projects in Canada for either monazite or bastnaesite, two major minerals used to produce rare earth metals. “We took the opportunity to build that midstream ahead of the upstream mining sector,” Crabtree said. “It’s a little like that chicken and the egg story; which do you do first? Do you put the mines in place, or the ability to process the ore? We’ve chosen the ability to process so that when Canadian mines come online, they will have a route to market for their product, other than just selling the ore on the international market.” The SRC also hopes to stimulate a rare earth supply chain in Canada. “If our only ambition is to mine the rare earths, we might make $10,000 a tonne exporting to the rest of the world,” he continued. “If we take it through the midstream process, the value goes up exponentially. For example, NdPr alloys can range from about $90,000 to $200,000 a tonne... Crabtree said representatives from over 40 countries have visited the facility in the last six months. “We have received incredible interest both domestically within Saskatchewan and Canada, and globally,” he added. “We are in detailed discussions with a significant number of companies at the moment about both the provision of various raw materials to the plant, but also for offtake of the products.” Although the facility is still in development, the potential for expansion is already being considered for the next two to three years. Crabtree explained expansion could be handled on two fronts, increasing the capacity to a full-commercial level of 12,000 tonnes of monazite processed annually and extending the midstream further down to start producing magnets. “This is the beginning of a really, really important sector for the Canadian economy,” said Crabtree.” (Source: CIM Magazine on June 2, 2023)

“The REE facility is actually three separate facilities sitting adjacent to each other. The first building contains the Monazite Processing Unit, which will process ore to produce a specific type of mineral containing mixed rare earths. Production then shifts to the second facility, the Solvent Extraction Unit that separates out the high value elements used in production of permanent magnets. The resulting material then goes to a third building that houses the Metals Smelting Unit, which converts the separate oxides into metal ingots.“ (Source:: ThinkSask.ca on June 23, 2023)

“The conversion of REE ore to individual REE products is done in two main stages. The first is the concentration of ore to mixed REE product. The second is the more complex separation stage that converts the mixed REE product to commercial pure-grade individual rare earth oxides. The Facility will address both stages of REE processing. Canada has some of the largest known reserves (measured) and resources (indicated) of REEs in the world, estimated at over 14 million tonnes of rare earth oxides (2021). REEs are used in a variety of industrial applications, including electronics, clean energy, aerospace, automotive and defence.” (Source: SRC)

”The processing facility will produce high-value REEs and magnet metals using REE minerals. It is expected to be the first fully integrated, commercial demonstration rare earth processing facility in North America. The facility will have hydrometallurgy, separation and metal smelting capabilities... Minister Responsible for SRC Jeremy Harrison said: “The design, fabrication and automation of these solvent extraction cells right here in Saskatchewan is helping to develop an innovative and secure rare earth element supply chain in North America.” The solvent extraction cells will be installed in the separation unit of the rare earth processing facility. The cells are used to perform the separation of mixed rare earth chloride, a liquid mixture that contains all 17 elements of the rare earths group. The mixture is separated into individual or grouped rare earth oxides.” (Source: Mining Technology on May 26, 2023)

Full size / Source / In August 2022, the SRC presented the first REE metal ingots made in Canada during a test run of its Metals Smelting Unit.

“REEs are a group of 17 minerals that aren’t exactly rare but are difficult to obtain in high enough concentrations. REEs can be recovered from monazite – a material rich in phosphate and other minerals that can be found in either sand or hard rock. To separate the REEs, the monazite must go through several stages of processing and purification. SRC’s Rare Earth Processing Facility consists of three crucial units: the Monazite Processing Unit, the Separation Unit and the Metal Smelting Unit. “Rare earths are not really different from other mining sectors when you look at the raw material,” says Dr. Imran [Vice-President of SRC’s Rare Earth Element Division]. “REEs are separated from impurities in the Monazite Processing Unit. Once that process is complete, the rare earths need to be separated from each other and that’s where the Solvent Extraction Unit comes in.” Solvent extraction is a necessary step that makes REEs more valuable. Once this stage is complete, the separated rare earths can be converted into metal in the Metal Smelting Unit. At SRC’s Facility, solvent extraction will separate the rare earths into three mixtures: medium/heavy REEs, lanthanum/cerium carbonate and a neodymium/praseodymium mixture, which then undergo further processing in the Metal Smelting Unit.“ (Source: SRC)

Full size / Source / ”Metals ingots, a rare earth metal, are the key ingredient used to manufacture permanent magnets which are used in electric vehicles, wind turbines, electronics, etc... “SRC is proud to be a world leader in rare earth element processing and separation technologies and now to be able to add metal processing to that list, is an incredible accomplishment,” SRC President and CEO Mike Crabtree said. “The production of rare earth metal is a very important, strategic step for the Facility, for Saskatchewan and in establishing a rare earth supply chain in Canada.” The fully integrated, three-stage Rare Earth Processing Facility will be the first-of-its-kind in North America and will be producing REE products for sale in the international market in 2024....” (Source: Saskatchewan.ca in August 2022)

“In August 2022, SRC announced that it produced the first rare earth metal ingots in Canadian history at its under construction Rare Earth Processing Facility using metal smelting technology. To date, 100 kg of NdPr (75% neodymium, 25% praseodymium) metal ingots have been produced. The Facility is the first of its kind in North America and includes three key stages of the REE midstream supply chain: concentration, separation and metal smelting. The Facility is on track to be commissioned and fully operational in 2024... The metal smelting process is not new and has been known for hundreds of years. However, there are currently no commercial-scale REE metal production options in North America. China has dominated this market since the 1990s, driven largely by two factors: low prices and state-backed investment in infrastructure and technology. SRC is looking to change that with the skills, expertise and knowledge it has gained over the years from both literature and hands-on experience through its research and development work in REEs and other industries.“ (Source: SRC)

”Metal smelting is a technology that falls under the pyrometallurgy umbrella of extractive metallurgies. Extractive metallurgy is the name for a group of technologies that extract the desired metals from mineral concentrates. There are two types of extractive metallurgies: hydrometallurgy and pyrometallurgy. As the names suggest, hydrometallurgy is where solution chemical reagents such as acid or cyanide are used to extract metals from mineral concentrates into a solution where they then move into downstream processes like precipitation or electrowinning that pull the “metals-in-solution” (or metal ions in solution) out into solid metallic form. Pyrometallurgy describes processes that use heat in the presence of other chemical agents to enable metals in mineral concentrates to be both extracted from the concentrate and converted to metals. It generally includes processes like calcining (thermal decomposition of a material), roasting (most commonly using heat and oxygen to oxidize sulphidic ore to oxides for further hydrometallurgical treatment), smelting and refining. Smelting and refining both involve thermal reactions with molten phases. Smelting is different from melting – melting is the process of liquefying a solid substance by heating, like butter in a hot pan. Smelting is the process by which a metal is obtained at temperatures beyond the melting point and therefore includes both the melting of ore and the extraction of metals from ores in their purest form... Refining generally refers to processes that take a smelted “product” and further purify and separate the metals in it. Both the smelting and refining of mineral concentrates have two outputs from their processes: purified metals and waste slag... SRC’s metal smelting operation aims to have the highest safety standards, to be energy efficient, and to achieve consistent product quality control and as much automation, as possible.” (Source: SRC) ”To minimize the risk for the environment, the plant will be designed to have zero liquid discharge, which means that there will be no solution waste streams that are released into the environment.” (Source: SRC)

"Most of the world has been dependent on foreign sources of critical materials for many decades. This import dependence can be a concern because it puts supply chains and material users at risk. With the evolution in both the auto and energy industries, hydrocarbon demand is diminishing and REE demand is increasing. The secure supply of rare earth elements and the resiliency of their supply chains are essential to meeting this demand. The REE supply chain is complex and poses many challenges to develop because there are many individual stages of the full REE production chain including mining, beneficiation, hydrometallurgy, separation, metal alloys, magnets, original equipment manufacturers (OEM) and finally end use." (Source: SRC)

Company Details

Commerce Resources Corp.

#1450 - 789 West Pender Street

Vancouver, BC, Canada V6C 1H2

Phone: +1 604 484 2700

Email: cgrove@commerceresources.com

www.commerceresources.com

Shares Issued & Outstanding: 99,846,805

Canada Symbol (TSX.V): CCE

Current Price: $0.11 CAD (07/18/2023)

Market Capitalization: $11 Million CAD

Germany Symbol / WKN (Tradegate): D7H0 / A2PQKV

Current Price: €0.07 EUR (07/18/2023)

Market Capitalization: €7 Million EUR

Previous Coverage

Report #36 “RIVAL IN THE REE SPACE: Commerce Resources at eye level with the only two major REE miners in the western world“

Report #35 “Major Step Forward: Commerce Resources succeeds in producing marketable mixed rare earth carbonate sample“

Report #34 “All Roads Lead To Ashram, Eventually“

Report #33 “Research & Advisory Firm looks into the Ashram REE & Fluorspar Project from Commerce Resources“

Report #32 “Already Big Ashram Gets Bigger And Bigger“

Report #31 “Fluorspar: The Sweet Spot for Quebec‘s Steel and Aluminium Industries“

Report #30 “Lean and Mean: A Fighting Machine“

Report #29 “Like A Phoenix From The Ashes“

Report #28 “SENKAKU 2: Total Embargo“

Report #27 “Technological Breakthrough in the Niobium-Tantalum Space“

Report #26 “Win-Win Situation to Develop One of the Most Attractive Niobium Prospects in North America“

Report #25 “The Good Times are Back in the Rare Earths Space“

Report #24 “Commerce Resources and Ucore Rare Metals: The Beginning of a Beautiful Friendship?“

Report #23 “Edging China out of Rare Earth Dominance via Quebec‘s Ashram Rare Earth Deposit“

Report #22 “Security of REE Supply and an Unstoppable Paradigm Shift in the Western World“

Report #21 “Commerce well positioned for robust REE demand growth going forward“

Report #20 “Commerce records highest niobium mineralized sample to date at Miranna“

Report #19 “Carbonatites: The Cornerstones of the Rare Earth Space“

Report #18 “REE Boom 2.0 in the making?“

Report #17 “Quebec Government starts working with Commerce“

Report #16 “Glencore to trade with Commerce Resources“

Report #15 “First Come First Serve“

Report #14 “Q&A Session About My Most Recent Article Shedding Light onto the REE Playing Field“

Report #13 “Shedding Light onto the Rare Earth Playing Field“

Report #12 “Key Milestone Achieved from Ashram’s Pilot Plant Operations“

Report #11 “Rumble in the REE Jungle: Molycorp vs. Commerce Resources – The Mountain Pass Bubble and the Ashram Advantage“

Report #10 “Interview with Darren L. Smith and Chris Grove while the Graveyard of REE Projects Gets Crowded“

Report #9 “The REE Basket Price Deception & the Clarity of OPEX“

Report #8 “A Fundamental Economic Factor in the Rare Earth Space: ACID“

Report #7 “The Rare Earth Mine-to-Market Strategy & the Underlying Motives“

Report #6 “What Does the REE Market Urgently Need? (Besides Economic Sense)“

Report #5 “Putting in Last Pieces Brings Fortunate Surprises“

Report #4 “Ashram – The Next Battle in the REE Space between China & ROW?“

Report #3 “Rare Earth Deposits: A Simple Means of Comparative Evaluation“

Report #2 “Knocking Out Misleading Statements in the Rare Earth Space“

Report #1 “The Knock-Out Criteria for Rare Earth Element Deposits: Cutting the Wheat from the Chaff“

Contact:

www.rockstone-research.com

Commerce Resources News-Disclaimer: Neither TSX Venture Exchange nor its Regulation Services Provider (as that term is defined in policies of the TSX Venture Exchange) accepts responsibility for the adequacy or accuracy of this release. Forward Looking Statements: This news release contains forward-looking statements, which includes any information about activities, events or developments that the Company believes, expects or anticipates will or may occur in the future. Forward looking statements in this news release include that we expect to complete a prefeasibility study for the Ashram Project, that an open-pit shell is planned for the Ashram Project; that the Ashram Deposit has the potential to be a long-term supplier to the met-spar and acid-spar markets; and that the Company is positioning to be one of the lowest cost rare earth producers globally. These forward-looking statements are subject to a variety of risks and uncertainties and other factors that could cause actual events or results to differ materially from those projected in the forward-looking information. Risks that could change or prevent these statements from coming to fruition include: that we may not be able to fully finance any additional exploration on the Ashram Project; that even if we are able raise capital, costs for exploration activities may increase such that we may not have sufficient funds to pay for such exploration or processing activities; the timing and content of any future work programs; geological interpretations based on drilling that may change with more detailed information; potential process methods and mineral recoveries assumptions based on limited test work and by comparison to what are considered analogous deposits that, with further test work, may not be comparable; testing of our process may not prove successful and even if such tests are successful, the economic and other outcomes may not be as expected; the availability of labour and equipment to undertake future exploration work and testing activities; the required permits to build and operate the envisaged open-pit shell may not be obtained in a timely or cost-effective manner, or at all; and despite the current expected viability of the Ashram Project, conditions changing such that even if metals or minerals are discovered on the Ashram Project, the project may not be commercially viable; The forward-looking statements contained in this news release are made as of the date hereof and the Company assumes no responsibility to update or revise such information to reflect new events or circumstances, except as required by law.

Rockstone Disclaimer: This report and the referenced news-release contain forward-looking information or forward-looking statements (collectively "forward-looking information") within the meaning of applicable securities laws. Forward-looking information is typically identified by words such as: "believe", "expect", "anticipate", "intend", "estimate", "potentially" and similar expressions, or are those, which, by their nature, refer to future events. Rockstone Research, Commerce Resources Corp. and Zimtu Capital Corp. caution investors that any forward-looking information provided herein is not a guarantee of future results or performance, and that actual results may differ materially from those in forward-looking information as a result of various factors. The reader is referred to Commerce Resources Corp.´s public filings for a more complete discussion of such risk factors and their potential effects which may be accessed through its respective profile on SEDAR at www.sedar.com. Please read the full disclaimer within the full research report as a PDF (here) as fundamental risks and conflicts of interest exist. The author, Stephan Bogner, holds equity positions in Commerce Resources Corp. and Zimtu Capital Corp., and thus will profit from volume and price appreciation in these stocks, and is being paid by Zimtu Capital Corp., which company also holds an equity position in Commerce Resources Corp. Note that Commerce Resources Corp. pays Zimtu Capital Corp. to provide this report and other investor awareness services. Also note that Commerce Resources Corp. has common directors with Zimtu Capital Corp.