Disseminated on behalf of Commerce Resources Corp. and Zimtu Capital Corp.

Today, Commerce Resources Corp. provided an update on the progress of the pilot plant for its Ashram REE Deposit in Quebec, Canada. The results demonstrate the robustness and scalability of the fundamentally critical front-end metallurgical process as the larger pilot scale is achieving even better results than the smaller bench scale.

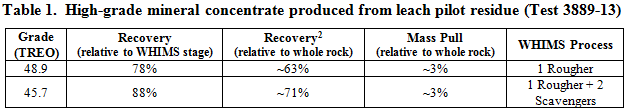

The Phase 2 of the pilot plant is designed to leach the bulk flotation concentrate, which is produced during Phase 1. This work has resulted in the production of a 49% TREO mineral concentrate at an overall recovery of 63%. With additional processing, a 46% TREO mineral concentrate at 71% recovery was achieved. The main take-aways from today’s news are as follows:

• Best results to date: The company achieved the same recovery (71%) as before on small/bench scale but managed to improve the grade from 44% to 46% TREO now on the larger/pilot scale, which is more reflective of a commercial operation.

• Further upside for improvements: There appears to be even more room for further improvements as the process is not yet optimized.

• Successful scale-up: The company has not only produced the best ever results in terms of mineral concentrate grade, but it was done by demonstrating that they can scale-up the flotation circuit as well as the leaching circuit, which are the most technically challenging parts of the front-end flowsheet. The front-end flowsheet is made up of 3 main process circuits/phases:

1) Flotation,

2) Leaching, and

3) Magnetic separation

(After flotation, a concentrate is produced, which is then leached, with the residue then taken through magnetic separation to produce a final mineral concentrate.)

The first 2 circuits have now been piloted successfully, where it was demonstrated that the flotation and leach processes are scalable. In order to test and confirm that the residue from the leach was good and appropriate as targeted, they first ran it through magnetics (WHIMS) on a smaller/bench scale, which produced very good results, so they know that the leach worked and confirmed that it separated well. Thus, the WHIMS just confirmed that the first 2 circuits were fully successful (it confirmed that the process is scalable for the flotation and leach).

Generally, the first 2 circuits/phases are the most critical (i.e. technically challenging), especially on a pilot level which is on a much larger scale than the bench scale. Multiplier Effect: When you notice a small operational or performance issue with an element in a small sample on bench scale, this may often lead to a big issue on the pilot level. Commerce confirmed today that everything they did on bench scale can be replicated on a much larger/pilot level, without any significant issues. This is a major milestone for the company going forward.

In addition, when testing the first 2 phases (flotation and leach), materials are consumed. In the magnetic separation however, apart from assays, no materials are consumed, which gives a lot more room for development and thus is more versatile and cost-effective. The magnetic separation remains to be tested on pilot level but no major issues are expected with that 3rd phase based on data collected to date.

Conclusion

Typically, it’s the pilot plant level where things can often go unexpectedly wrong or where small issues, recognized at bench scale, multiply into big problems at large, more commercial like levels. Thankfully, as taken from today’s news, this is not the case with Commerce Resources and the pilot plant for its Ashram REE Deposit as it achieved a key milestone with the highest grade of a mineral concentrate ever produced at significant recovery by the company, and whereas this was achieved at a crucial large scale (pilot level). Rockstone is not aware of any other junior REE company ever having produced anything equivalent to this on a large scale, and further, where there is still room for further improvement.

As it is said “Bigger is Better” – and this statement has never been more true than when it is applied to the metallurgy for a resource project. As when any company looks to scale up from successful metallurgy on the laboratory sized sample (also called the bench scale), to the pilot plant level, this may mean an increase of anywhere from ten times, and up to several thousand times larger sample size. This exponential increase in size should give you, in your mind’s eye, a picture of the scales of Blind Justice – that is, of the Multiplier Effect, which holds both the promise of the successful repeat of the process, or the possibility that the overall process when scaled up to the larger sample size, simply does not work. This is to say that small negative items on the smaller sample size are actually increased on the larger sample size to the extent that they become a “flow sheet killer”. This is why successfully piloting is so critical to the success of a project.

No-one should ever expect exactly the same set of results on the larger sample size; there are just too many variables and too much that can go wrong when sample size is amplified to such an extent as it needs to be done in this industry. However, in the case of Ashram, they have not only successfully repeated the smaller sample size results, they have actually had an improvement with the production of the highest grade mineral concentrate that the company has ever produced, and on the largest sample size the company has ever used!

Commerce has now successfully scaled up the process, which has derisked the entire project substantially, while at the same time improved the grade of the mineral concentrate. These are 2 very valuable aspects to note.

More news in this respect is expected during the next weeks giving the sound impression that Commerce is on the right track with its pilot plant, ultimately supplying samples of a mixed rare earth carbonate/chloride concentrate to potential joint venture partners.

Commerce’s President, Chris Grove, commented in today’s press release:

“We are highly encouraged by these results from the 2nd Phase of the pilot plant program. The production of these high-grade mineral concentrates using piloted material as feed is a significant milestone, with the ongoing program continuing to demonstrate that the flowsheet for the Ashram Deposit is simple, robust, and scalable using standard commercial methods.”

The next Rockstone article is already in the making providing a straight-forward comparison between Commerce Resources and Lynas Corp., as well as giving reasons why Lynas is still in production today.

Press Release:

Commerce Resources Corp. Achieves Key Milestones for the Ashram Rare Earth Project

October 5, 2015 - Commerce Resources Corp. (TSXv: CCE, FSE: D7H, OTCQX: CMRZF) (the “Company” or “Commerce”) is pleased to announce the achievement of key metallurgical milestones with the successful completion of a leach mini-pilot plant1 and the subsequent production of the highest-grade mineral concentrate to date from the Company’s 100% owned Ashram Rare Earth Deposit.

The work was completed as part of the 2nd Phase of the pilot plant, designed to leach bulk flotation concentrate produced during the first phase of the pilot plant. Both continuous and batch leach pilots have now been completed, as well as bench scale testing of the piloted material through to a final mineral concentrate to demonstrate the robustness of the entire process.

Highlights include:

• Successful demonstration that the leach process is robust and scalable from bench level (300 kg) using both continuous and batch methods

• Production of a 49% TREO mineral concentrate at an overall recovery of ~63% using residue produced from the leach pilot

o 46% TREO at ~71% recovery with additional processing

Company President Chris Grove states, “We are highly encouraged by these results from the 2nd Phase of the pilot plant program. The production of these high-grade mineral concentrates using piloted material as feed is a significant milestone, with the ongoing program continuing to demonstrate that the flowsheet for the Ashram Deposit is simple, robust, and scalable using standard commercial methods.”

The main objective of the continuous pilot is to demonstrate the leach process (using HCl) on a continuous and scaled up basis (150 kg) to evaluate material handling and performance in a manner similar to a commercial operation. The objective of the batch leach pilot is to demonstrate additional scale up (300 kg) and to produce larger quantities of leach residue at the defined parameters.

The continuous leach pilot was comprised of a series of eight glass cascading vessels that was fed flotation concentrate continuously (154 kg total) for a period of 145 hours, producing 47 kg of primary leach residue. The batch leach pilot was comprised of one large vat that was fed flotation concentrate in one single dose (i.e. batch) of 307 kg, producing 100 kg of primary leach residue. A secondary leach was completed on the batch pilot residue with the combined overall REE recovery exceeding 99%2, as targeted.

In order to fully evaluate the quality of the residues produced from the leach pilot plant, several samples were bench processed through the Wet High Intensity Magnetic Separation (WHIMS) stage to produce a final mineral concentrate to use for downstream hydrometallurgical processing. This testwork produced the best mineral concentrate to date for the Ashram Deposit, with potential for additional improvement remaining (Table 1).

The pilot plant results to date (flotation and leach) are encouraging and indicate that the Ashram flowsheet is robust at larger scales and is able to produce rare earth mineral concentrate of >45% TREO at high overall recovery. This compares favorably to major hard-rock producers globally.

The 2nd phase of the pilot plant is ongoing, with the opportunity to further optimize as additional flotation concentrate remains to be processed. This pilot plant is part of a larger program to confirm the scalability of the overall flowsheet and produce several kilograms of mixed rare earth carbonate concentrate (REC), and mixed rare earth chloride concentrate (RECl).

(1) Approximately 1-2 tonnes of flotation concentrate is anticipated to be processed during the HCl leach piloting. This size throughput tonnage is sometimes referred to as a ‘mini-pilot plant’ as opposed to a ‘pilot plant’.

(2) The secondary leach results in a minor percentage of REE partitioning to the liquor phase. However, subsequent testing on similar liquors indicates that the REEs may be fully recovered selectively as a high-grade precipitate, resulting in a negligible loss in the stage (i.e. effectively >99% REE recovery in the leach stage)

NI 43-101 Disclosure: Darren L. Smith, M.Sc., P.Geol., Dahrouge Geological Consulting Ltd., a Qualified Person as defined by National Instrument 43-101, supervised the preparation of the technical information in this news release. Eric Larochelle, Eng., and Alain Dorval, Eng., Manager-Process, Mining and Mineral Processing, of Roche Ltd., Consulting Group, Qualified Persons as defined by National Instrument 43-101, reviewed the technical information presented in this news release.

About the Ashram Rare Earth Element Deposit

The Ashram Rare Earth Element (REE) Deposit is located in north-eastern Quebec. The Deposit has a measured resource of 1.6 million tonnes (Mt) at 1.77% TREO, an indicated resource of 27.7 Mt at 1.90% TREO, and an inferred resource of 219.8 Mt at 1.88% TREO.

The REEs at Ashram occur primarily in the mineral monazite and to a lesser extent in bastnaesite and xenotime. These minerals dominate the currently known commercial extraction processes for rare earths. The Ashram Deposit mineralization has an REE distribution with enrichment in the critical and magnet feed REEs (Nd, Pr, Eu, Tb, Dy, and Y).

A Preliminary Economic Assessment (PEA) was completed in May of 2012 by SGS-Geostat of Montreal (Blainville) (see news release May 24, 2012). The PEA is based on a 4,000 tonne per day open-pit operation with an initial 25-year mine life, a pre-tax Net Present Value (NPV) of $2.32 billion at a 10% discount rate, a pre-tax/pre-finance Internal Rate of Return (IRR) of 44%, and a pre-tax/pre-finance payback period of 2.25 years.

The PEA (revised date January 7, 2015) is preliminary in nature, and includes inferred mineral resources that are considered too speculative geologically to have the economic considerations applied to them that would enable them to be categorized as mineral reserves, and there is no certainty that the PEA will be realized. Mineral resources are not mineral reserves as they do not have demonstrated economic viability. The current Ashram Technical Report dated January 7, 2015 explains why no after-tax case is included, and that a combined tax rate of around 32.5% may apply to production.

With respect to the ongoing Pre-feasibility Study (PFS), the results of the programs described in this news release will be incorporated, along with other necessary technical data including geological and engineering studies, into the PFS with costs and benefits to be described in more detail therein.

About Commerce Resources Corp.

Commerce Resources Corp. is an exploration and development company with a particular focus on deposits of rare metals and rare earth elements. The Company is focused on the development of its Ashram Rare Earth Element Deposit in Quebec and the Upper Fir Tantalum and Niobium Deposit in British Columbia.

For more information please visit the corporate website at www.commerceresources.com or contact Investor Relations at 604.484.2700 or info@commerceresources.com.

Company Details

Commerce Resources Corp.

#1450 - 789 West Pender Street

Vancouver, BC, Canada V6C 1H2

Phone: +1 604 484 2700

Email: cgrove@commerceresources.com

www.commerceresources.com

Shares Issued & Outstanding: 216,462,364

Canadian Symbol (TSX.V): CCE

Current Price: $0.075 CAD (Oct. 2, 2015)

Market Capitalization: $16 million CAD

German Symbol / WKN: D7H / A0J2Q3

Current Price: €0.05 EUR (Oct. 2, 2015)

Market Capitalization: €11 million EUR

.png)

Direct link to above chart (15 min. delayed): http://schrts.co/wR62L5

.png)

Direct link to above chart (15 min. delayed): http://schrts.co/kAtslu

Analyst Coverage

Research #11 “Rumble in the REE Jungle: Molycorp vs. Commerce Resources – The Mountain Pass Bubble and the Ashram Advantage“

Research #10 “Interview with Darren L. Smith and Chris Grove while the Graveyard of REE Projects Gets Crowded“

Research #9 “The REE Basket Price Deception & the Clarity of OPEX“

Research #8 “A Fundamental Economic Factor in the Rare Earth Space: ACID“

Research #7 “The Rare Earth Mine-to-Market Strategy & the Underlying Motives“

Research #6 “What Does the REE Market Urgently Need? (Besides Economic Sense)“

Research #5 “Putting in Last Pieces Brings Fortunate Surprises“

Research #4 “Ashram – The Next Battle in the REE Space between China & ROW?“

Research #3 “Rare Earth Deposits: A Simple Means of Comparative Evaluation“

Research #2 “Knocking Out Misleading Statements in the Rare Earth Space“

Research #1 “The Knock-Out Criteria for Rare Earth Element Deposits: Cutting the Wheat from the Chaff“

Disclaimer: Please read the full disclaimer within the full research report as a PDF (here) as fundamental risks and conflicts of interest exist.